10kW+ High Power Laser Cutting

10kW+ high power laser cutting leverages laser systems with power exceeding 10kW for precise processing of diverse materials. The high-energy laser beam rapidly heats, melts, or vaporizes the material, creating clean and accurate cuts.

Laser cutting offers the following advantages:

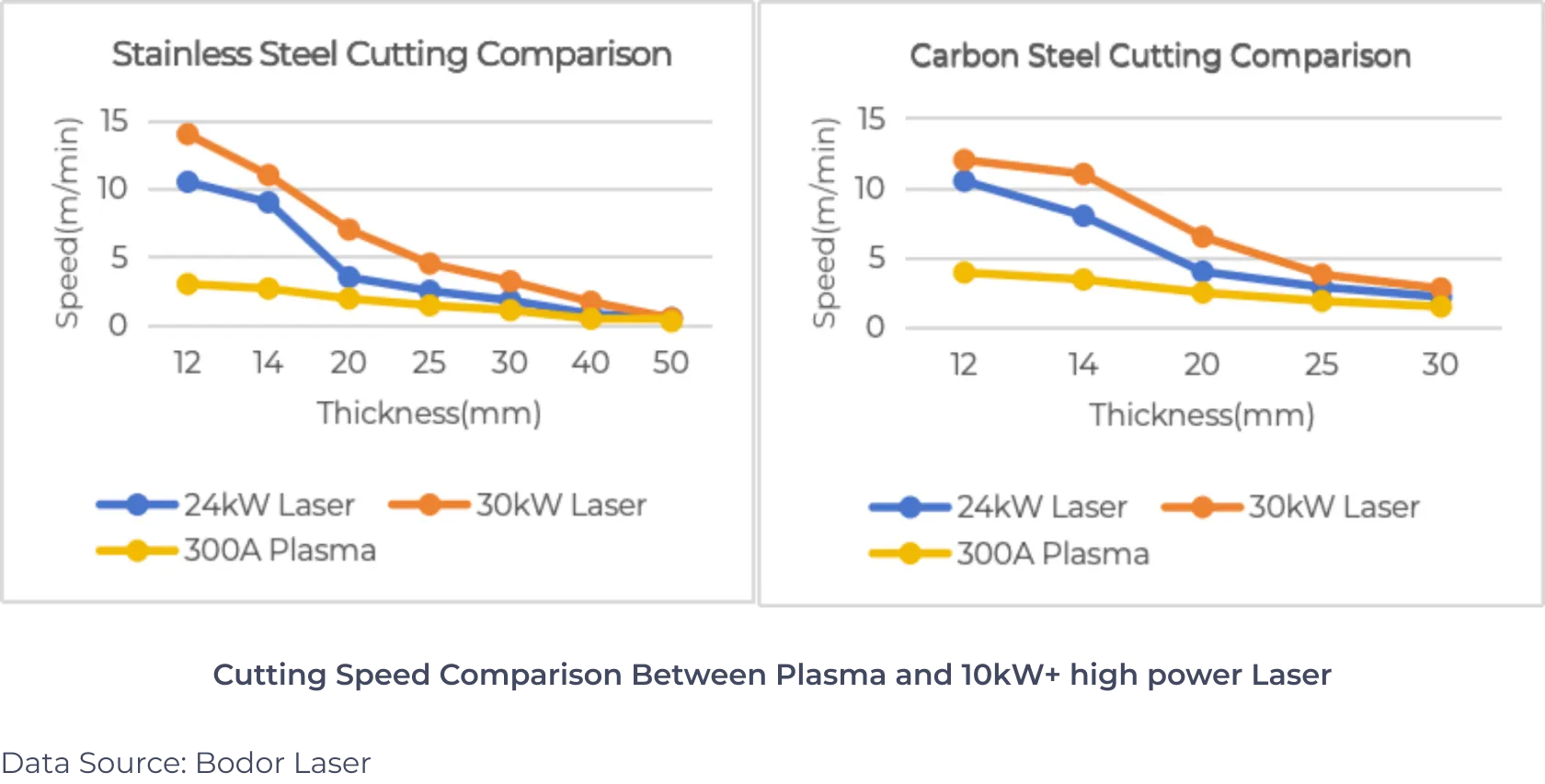

1. Speed: 10kW+ high power laser cutting offers a significant advantage in terms of speed. Compared to plasma cutting, laser cutting achieves cutting speeds up to 3 times faster. For instance, suppose a company is using a 30kW laser cutting machine to process 12mm carbon steel and operating it 10 hours per day, 25 days per month. By utilizing laser cutting technology, this company can process approximately an additional 120,900 meters of carbon steel per month. This increase in productivity translates to higher earnings, allowing the company to recoup the cost of the laser cutting machine in a much shorter time.

2. Superior Precision: When it comes to precision, 10kW+ high power laser cutting is in a league of its own. This technique is perfect for intricate designs and close tolerance requirements, as it boasts unparalleled accuracy. With a high-density laser beam used for cutting, the positioning accuracy is an impressive 0.14mm, far surpassing plasma cutting's 0.4mm accuracy. Laser cutting also produces a much narrower kerf, measuring only 0.4mm compared to plasma cutting's 5mm, which is especially advantageous for cutting intricate designs. Precision is essential in industries such as medical and precision instrument manufacturing, where accuracy is crucial for ensuring optimal device performance and safety. Laser cutting is undoubtedly the superior choice in such industries.

3. Adequate Cutting Edge Quality: With the heat-affected zone in laser cutting limited to a mere 0.1-0.4mm, materials experience minimal deformation. Cutting edges generally span 0.2-1.6mm, yielding smooth edges and surfaces devoid of slag formation, thereby significantly enhancing the quality of materials. Take the electronics manufacturing industry as an example, the surface and edge of metal parts should be smooth, burr-free, and scratch-free to reduce friction, wear, and corrosion, ensuring the performance and long lifespan of the devices.

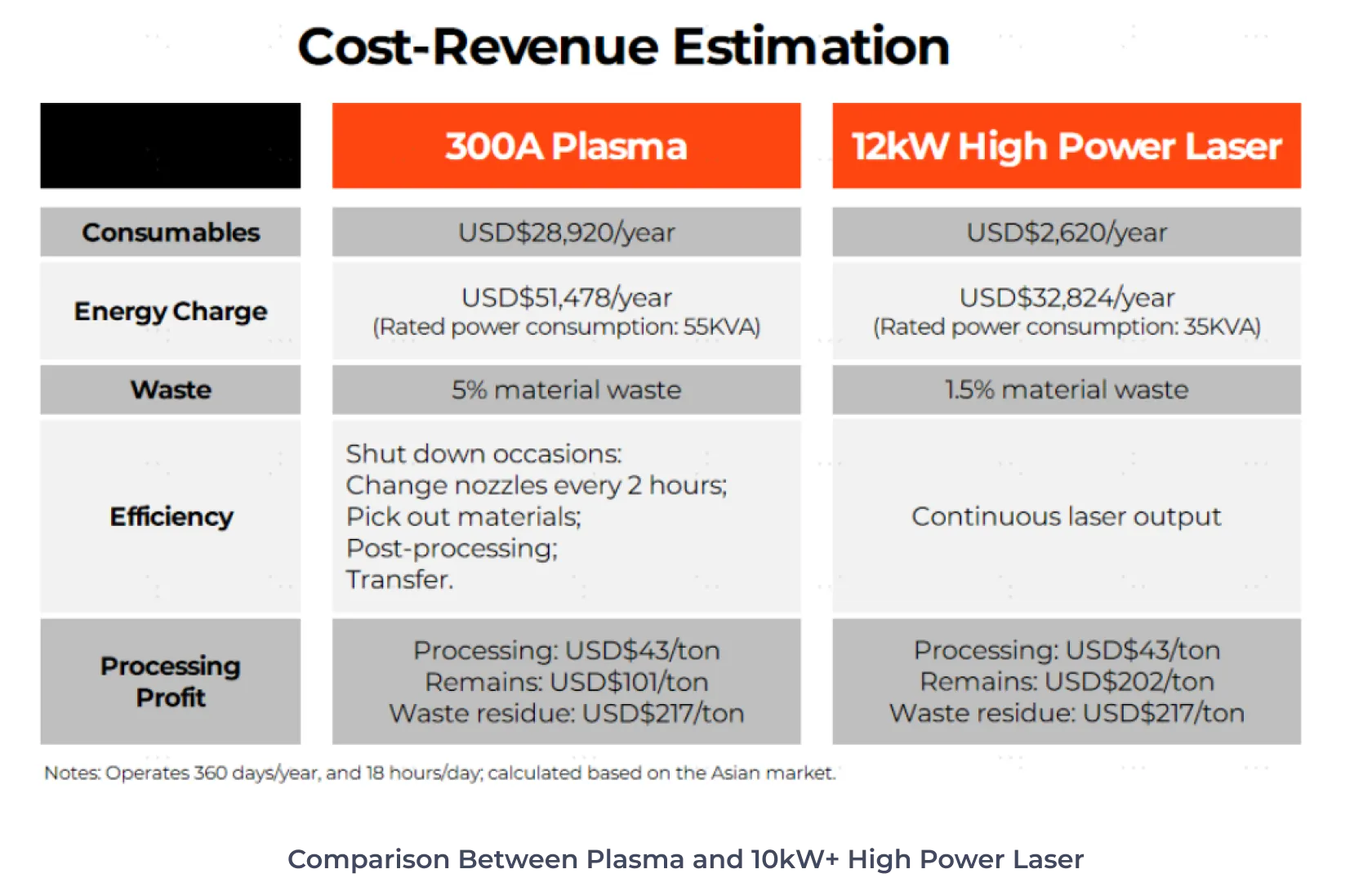

4. Lower Operational Costs: Unlike traditional cutting methods, laser cutting machines utilize a high-energy laser beam to cut materials without any physical contact, resulting in reduced maintenance costs and a longer lifespan. Additionally, laser cutting machines are highly automated and require minimal operator intervention, translating to lower labor costs and increased productivity. Furthermore, laser cutting machines make the best of materials and consume less energy than traditional cutting machines, resulting in lower operating costs.

However, laser cutting also presents certain limitations:

1. Higher Initial Cost: Laser cutting machines are typically more expensive than plasma cutting devices, representing a barrier to entry for start-ups, small and medium-sized enterprises.

2. Thickness Constraint: Although ultra-high-power laser cutting is improving its ability to cut thicker metals, it still performs better with metals that are less than 60mm in thickness.

Plasma Cutting

Plasma cutting is a solution for electrically conductive materials, especially metals. The process uses ionized gas or plasma to generate high temperatures that melt the metal, allowing the accelerated stream to eliminate the molten material and create clean cuts.

The benefits of plasma cutting include:

1. Thickness: Plasma cutting is good at handling thicker metal plates with ease. It can cut through aluminum and stainless steel up to 160mm, while steel can be sliced up to 100mm.

2. Less Initial Investment: Plasma cutting machines are more affordable than laser cutting machines in terms of initial costs, making them accessible to smaller businesses at their early stages.

3. Easy Accessibility: According to Yahoo Finance, the global plasma cutting machine market size is estimated to increase by USD 1,119.84 million between 2022 and 2027, garnering popularity as a tool for cutting through metals. As the plasma cutting machine becomes more widespread, it can be produced on a large scale.

Nonetheless, plasma cutting also reveals several disadvantages:

1. Reduced Precision: Plasma cutting may not be the best option for high-precision applications and intricate designs due to the larger kerf width it produces. It is commonly used in some industries that do not strictly request precision, such as construction and agricultural machinery manufacturing industries.

2. Inferior Surface Quality: The plasma cutting process is highly likely to leave slag, dross, and rough edges that may require post-processing, such as grinding and burnishing, to make the surfaces and edges of metals smooth enough to adapt to later assembly.

3. Conspicuous Heat-Affected Zone: The process generates a heat-affected zone that can be relatively extensive, typically ranging from 0.5 to 2.0mm. This can potentially result in metal distortion.

4. Not Eco-friendly: Plasma cutting is known to produce a significant amount of metal dust and noise during operation, which can be detrimental to the health and well-being of workers and the surrounding environment. Based on the increasingly stringent international environmental protection requirements, manufacturers should carefully review local environmental regulations when making choices.

How to Choose Between Laser Cutting and Plasma Cutting

After reviewing the previous information, you may have a better understanding of the approach your business requires for cutting operations. However, making the final decision can still be a daunting task. This article provides several suggestions that help you make an informed decision that aligns with your business needs and goals.

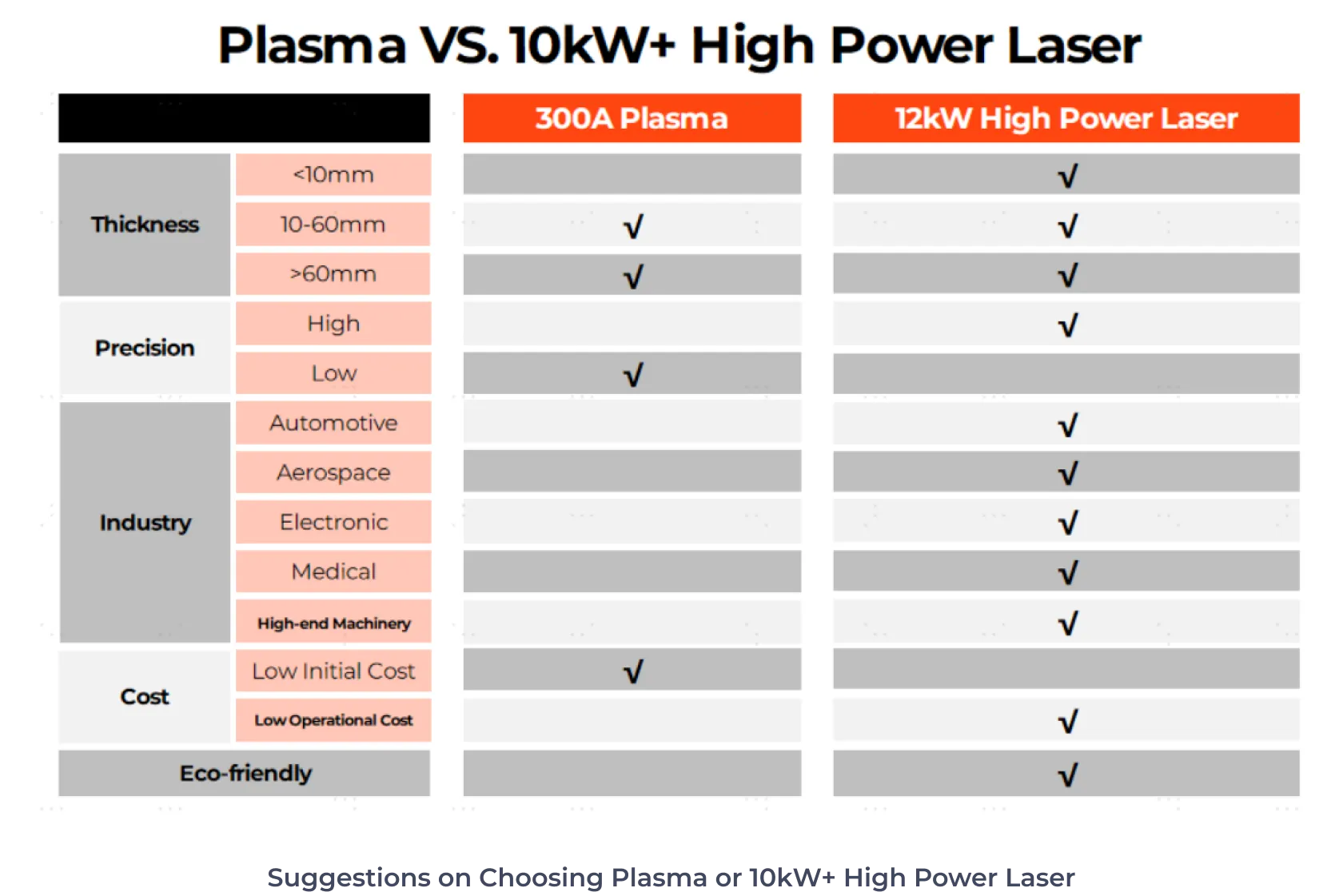

By the material thickness specifications necessary for your business operations, the following recommendations are provided:

· For materials with a thickness below 10mm, a laser-based solution is advised;

· For materials within the 10mm to 60mm thickness range, both laser and plasma options are deemed appropriate;

· For materials with a thickness exceeding 60mm, a plasma-based approach is considered the optimal choice

Should your enterprise operate within the aerospace, medical, automotive, or other industries requiring equipment with superior precision and accuracy during fabrication procedures, it is customary to utilize laser cutting as the preferred method.

For an emerging business with constrained financial resources and an inclination to first assess the market environment, the deployment of plasma cutting devices or introductory laser cutting equipment may alleviate fiscal strain.

For established organizations pursuing enduring and sustainable resolutions, allocating resources toward ultra-high-power laser cutting is substantiated.

We highly recommend the bodor laser brand, please visit www.bodor.com for more information